Testing....

Recently I had a chat with my friends and fellow potters, and the conversation turned to glazes and glaze tests. We all have favourite ways to test, record and document the glazes....and during the conversation I promised to write a blog about my way of testing and documenting.

As some test tiles just came out of the kiln, it is a perfect opportunity to tell you about it.

First, about the test tiles:

This is my extruder die ( for 2 different extruders):

It has smooth and rounded top edge and a few notches to show how the glaze behaves on the textured surface. I tend to extrude a big batch in one go, to last me at least a year. That way I always have tiles on hand.

When I extrude the tiles, I score a line at the bottom of the vertical surface, just above the angle. That makes it easy to break the bottom off for filing:

Once I forgot to do the score line and had to use the angle grinder for this step.

I store the tiles on A4 size 3 mm thick MDF board fitted with stapled elastic on both sides:

It helps to cut all the tiles the same size :)

I use the same format to write the recipes on the A4 page, and that way I have clear visual reference:

Someone said that the main difference between the Scientist and the Artist is that Scientists keep (better) notes.

As some test tiles just came out of the kiln, it is a perfect opportunity to tell you about it.

First, about the test tiles:

This is my extruder die ( for 2 different extruders):

When I extrude the tiles, I score a line at the bottom of the vertical surface, just above the angle. That makes it easy to break the bottom off for filing:

Once I forgot to do the score line and had to use the angle grinder for this step.

I store the tiles on A4 size 3 mm thick MDF board fitted with stapled elastic on both sides:

I use the same format to write the recipes on the A4 page, and that way I have clear visual reference:

The further benefit is that the tiles are always stored together with the others tested in the same batch,so the whole series is easily viewed together.

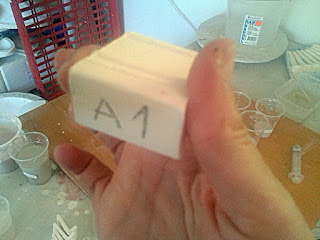

It is easy to pull the tiles out for the close comparison. All of them have their ID number written on the back, so they will not be mixed up.

Because the tiles are fired vertically, I can see how the glaze moves in the firing and how it behaves on the top lip. How the glaze breaks over, or covers the raised line is the good indicator of how will it show textured surfaces.

I have made several sturdy MDF boxes with handles and slots for the tile trays.They can be stored vertically or horizontally, and are easily and safely carried to workshops.

One box stores (I think) 640 glaze tests.

Slots in the box are easily made with glueing and stapling strips of 3 mm MDF at equal distances.

:)

More about glaze tests

You have probably figured out that I am fairly organized when it comes to glaze testing.(Ok, we could use a stronger term, but I wont).

Every now and then a glaze catches my attention that I want to explore fully, so I came up with a series of test that will give me the widest range of colours with the least amount of effort and repetition.

and that Heavenly Turquoise definitely deserves further testing.

I have mixed 2 kg of glaze base (removing the colourant) and sieved it.

Protect your lungs!!

After dividing the glaze into smaller batches ( see bottom of the chart on the top of the post)

I use precision scales to accurately weigh the colouring oxides. As per chart, I need 1% chromium oxide, which is in this case equivalent to 1g.

sieved:

And positioned in the triaxial formation.

This is Triaxial A:

Then the fun begins. I use a syringe to accurately measure 15 ml into second row cups, 10 ml into 3rd row, 5 ml into 4th row and none into 5th.

Every now and then a glaze catches my attention that I want to explore fully, so I came up with a series of test that will give me the widest range of colours with the least amount of effort and repetition.

I have mixed 2 kg of glaze base (removing the colourant) and sieved it.

Protect your lungs!!

As a rule of thumb, I use same weight of water as powder. As I'm mixing a 2 kg batch, I'm mixing it into 2 l of water.

After the sieving, dipping my fingers in glaze will tel me it's thickness. If you can't see your nails - the glaze is too thick. If you can see every little hair on your fingers, it is probably too thin. This one is about right.

After dividing the glaze into smaller batches ( see bottom of the chart on the top of the post)

I use precision scales to accurately weigh the colouring oxides. As per chart, I need 1% chromium oxide, which is in this case equivalent to 1g.

All of them a weighed:

And labeled:

Mixed:

This is Triaxial A:

Then the fun begins. I use a syringe to accurately measure 15 ml into second row cups, 10 ml into 3rd row, 5 ml into 4th row and none into 5th.

By the time I'm done with the corner A, it looks like this:

repeat the same with the other 2 corner cups.

It is easy to see the 3 different colour glazes:

stir thoroughly:

label test tiles:

dip:

repeat until all done:

Wash all cups, sticks etc, and repeat for the 2nd, 3rd, 4th, 5th and 6th triaxial....

I also use some extra tiles to combine the leftovers. You can see it in the top left corner of the above chart.

G is the base glaze with no additions....etc

I have just used every single bisque fired test tile I had in the studio...108 of them.

And they are fired

Inpatient as I am, I opened the kiln and got the tests out with the thick gloves. I have a lovely variety of colours here, and texture is really nice:

They start making more sense when I organize them into triaxial blends:

here are a few close ups. I anticipate many hours of playing , sorting and examining....

Red tile is the only one with the stain as colourant (10% signal red). I run out of test tiles and base glaze to test 7.5%, 5% and 2.5%....for now.....

Interesting glaze. I am getting green from cobalt, pale blue from copper and yellow from iron. No chrome - tin pinks though. I like the darker blush at the bottom edge of some tiles.

They start making more sense when I organize them into triaxial blends:

here are a few close ups. I anticipate many hours of playing , sorting and examining....

Red tile is the only one with the stain as colourant (10% signal red). I run out of test tiles and base glaze to test 7.5%, 5% and 2.5%....for now.....

Interesting glaze. I am getting green from cobalt, pale blue from copper and yellow from iron. No chrome - tin pinks though. I like the darker blush at the bottom edge of some tiles.

Thursday, 14 September 2017

Let’s talk about glazes…

I love the science, mystery and complexity of glazes, and occasionally I teach the ‘Understanding Glazes” course. Some of the students that come to the course are disappointed at the lack of straight answers and quick fixes, and others get mesmerized by the unlimited possibilities. Mostly, I teach Glaze technology as a cooking class. And it makes sense. There are limited number of ingredients, some of them local, you mix them together in various proportions and heat them to the various temperatures. The “mystery and magic” of transformation of raw ingredients into the glassy surfaces comes from unfamiliarity. Most of us can name at least 5 different foods made from eggs, fat, water and wheat flour in different ratios. (pancakes, bread, pasta, dumplings, profiteroles, omelette, scrambled eggs, egg sandwich, pastry, basic mayonnaise, custard……). What happens if I expand it to “any flour” instead of “wheat flour”? What if we allow “additives” (spices, sweeteners, flavours)?

Yes, very soon we can say that the possibilities are almost limitless.

So, why don’t we see the “magic” in making an omelette the same way we do when we mix glazes?

For most of us it is about familiarity. If we were exposed to glaze materials as often and from as young age as we are to cooking, we would be just as comfortable with mixing a glaze as we are with scrambling eggs for breakfast.

There is another thing, and that is that we (humans) prefer simple answers, even to the complex questions.

We have so much going on in our lives…most of the time we can’t really cope even with the full scope of the sensory input available (smells, sounds, visual stimuli, movement…) let alone more complex matters (relationships, complex problem solving…) so our brains shut down the flood gates in front of the complexity and only open the little doors: just give me the simple answer I can trust and don’t have to think too much about it.

Yet, on the other hand, we (humans) fully accept and understand that some questions don’t have simple answers.

And that brings me to the new idea. The next step from the “cooking class” in understanding glazes is the “psychology class”.

It is a big jump, but bear with me for a while.

Psychology, in simplified terms, is mostly about the relationships. It is also something that although only a few of us study, most of us are familiar enough with to understand that there are no simple answers to some (in terms of psychology, I dare say most) questions.

How do I find the perfect partner?

(most of the mature adults will only smile )

How do I make the grey speckle glaze that looks like this:….?

(the answer is the same as to the question above: you won’t know until you test it)

And here are two images which prompted this philosophical tirade:

The glazes on the images are the same, applied in the same manner, fired on the same kiln shelf. The only difference is the clay body. Both are white stoneware.

One variable that we don’t even take in serious consideration most of the time, as long as it is the same general type…

I was wondering if you could help me?

ReplyDeleteI'm trying to identify which of your extra tiles is which in your triaxial blends, I love the pink and blue under C13 and14. And do you have a recipe for the lovely caramel colour From the second photo of you stoneware to midfire piece?